The Five Focusing Steps: A Step-by-Step Guide to Achieving Operational Excellence

The Theory of Constraints (TOC) is a powerful management philosophy that helps organizations achieve operational excellence by identifying and addressing constraints. At the heart of TOC lies the Five Focusing Steps, a systematic approach to optimizing performance and achieving remarkable results. In this article, we’ll delve into the Five Focusing Steps, exploring their significance, application, and benefits.

What are the Five Focusing Steps?

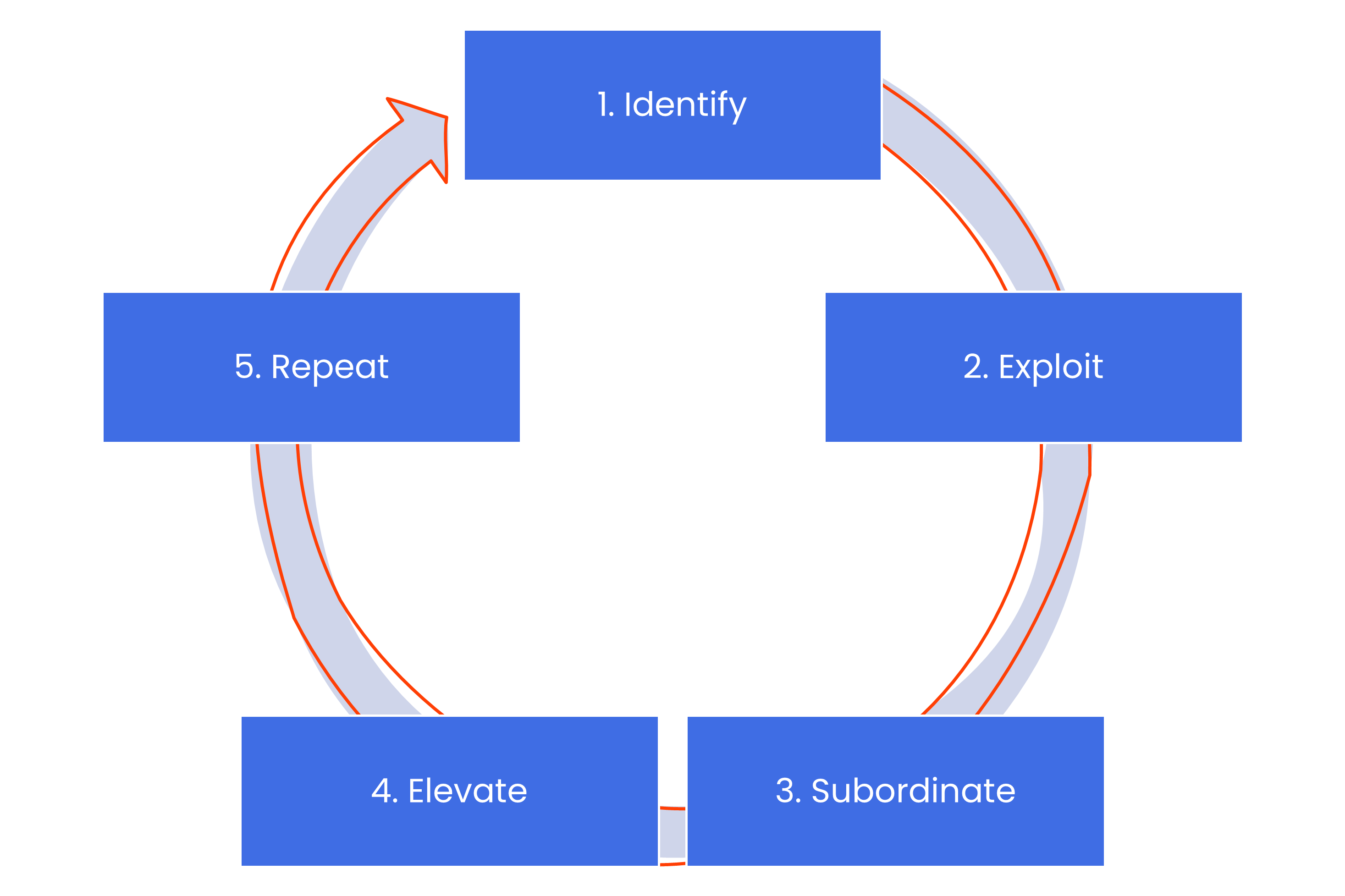

Developed by Dr. Eliyahu M. Goldratt, the Five Focusing Steps provide a structured methodology for identifying and addressing constraints, thereby improving overall system performance. These steps are:

- Identify: Identify the constraint(s) limiting system performance.

- Exploit: Exploit the constraint(s) to maximize their utilization.

- Subordinate: Subordinate everything else to the constraint(s).

- Elevate: Elevate the constraint(s) to increase capacity.

- Repeat: Repeat the process to ensure ongoing improvement.

Step 1: Identify

The first step is to identify the constraint(s) limiting system performance. Constraints can be physical (e.g., equipment capacity), policy-related (e.g., outdated procedures), or market-related (e.g., demand fluctuations). To identify constraints, ask:

- What limits our ability to achieve our goals?

- Where are the bottlenecks in our process?

- What resources are underutilized or overutilized?

Step 2: Exploit

Once the constraint(s) are identified, exploit them to maximize their utilization. This involves:

- Ensuring the constraint operates at maximum capacity

- Minimizing downtime and setup times

- Optimizing production schedules

- Prioritizing tasks based on constraint utilization

Step 3: Subordinate

Subordinate everything else to the constraint(s). This means:

- Aligning non-constraint resources to support the constraint

- Adjusting production schedules to match constraint capacity

- Reducing waste and inefficiencies in non-constraint areas

- Focusing on quality and reliability to minimize rework

Step 4: Elevate

Elevate the constraint(s) to increase capacity. This involves:

- Investing in new equipment or technology

- Implementing process improvements

- Increasing staffing or training

- Enhancing supplier relationships

Step 5: Repeat

The final step is to repeat the process to ensure ongoing improvement. As constraints are addressed, new ones may emerge. Continuously monitoring and reassessing the system ensures sustained progress.

Benefits of the Five Focusing Steps

Implementing the Five Focusing Steps offers numerous benefits, including:

- Improved productivity and efficiency

- Increased capacity and throughput

- Enhanced quality and reliability

- Reduced waste and costs

- Improved decision-making and prioritization

- Increased profitability and competitiveness

Real-World Applications

The Five Focusing Steps have been successfully applied across various industries, including:

- Manufacturing: Improved production scheduling and inventory management

- Healthcare: Optimized patient flow and resource allocation

- Logistics: Enhanced supply chain management and delivery times

- Finance: Streamlined processes and reduced transaction times

Conclusion

The Five Focusing Steps provide a structured approach to achieving operational excellence by identifying and addressing constraints. By applying these steps, organizations can unlock their full potential, improve performance, and sustain competitiveness in today’s fast-paced business environment.

Additional Resources

For further learning:

- “The Goal” by Dr. Eliyahu M. Goldratt